Fresh grow their business and install rugged computers from JLT onto new warehouse forklifts

Fresh AB is one of the leading Nordic suppliers of residential ventilation products and systems. Since its start in 1969 Fresh has delivered solutions and systems for better indoor environments, manufactured in Sweden and delivered to customers across the globe. Fresh is owned by Volution Group plc and is part of the same group as Pax, Klimatfabriken and VoltAir System in Sweden.

Growing operations meant moving to a bigger warehouse

After almost 50 years in Gemla, a small municipality in the southern parts of Sweden, Fresh has now moved to new facilities in the middle of Växjö city center. Andreas Rosell, Department Manager Logistics and Production at Fresh manages over 20 employees and is running the production with ambitions to take them all to the next level.

“We’ve had rapid growth lately and wanted new, modern facilities better suited for our needs. The central location in the middle of Växjö also makes us a more attractive employer. We’re now working to increase collaboration with other companies within the group to better integrate our businesses. In the near future, I hope that we will share a common distribution center with Pax in these facilities”, says Andreas Rosell.

From pen and paper to modern ways of working, using rugged computers

Fresh was previously using pen and paper in their logistic operations, but when they changed to a new ERP system from Monitor, they recognized new ways of working that would increase efficiency. The forklifts in the warehouse were promptly equipped with JLT devices and connected to the Monitor system.

“The warehouse floor was very uneven and had holes in it, so the forklifts were exposed to severe vibration and shocks, so we really needed the rugged devices from JLT. Since the forklifts were used both inside the warehouse and outdoors on the yard the computers were also facing all kinds of weather variations we have here in the Nordic climate. But the devices from JLT hold up against all of these challenges.”

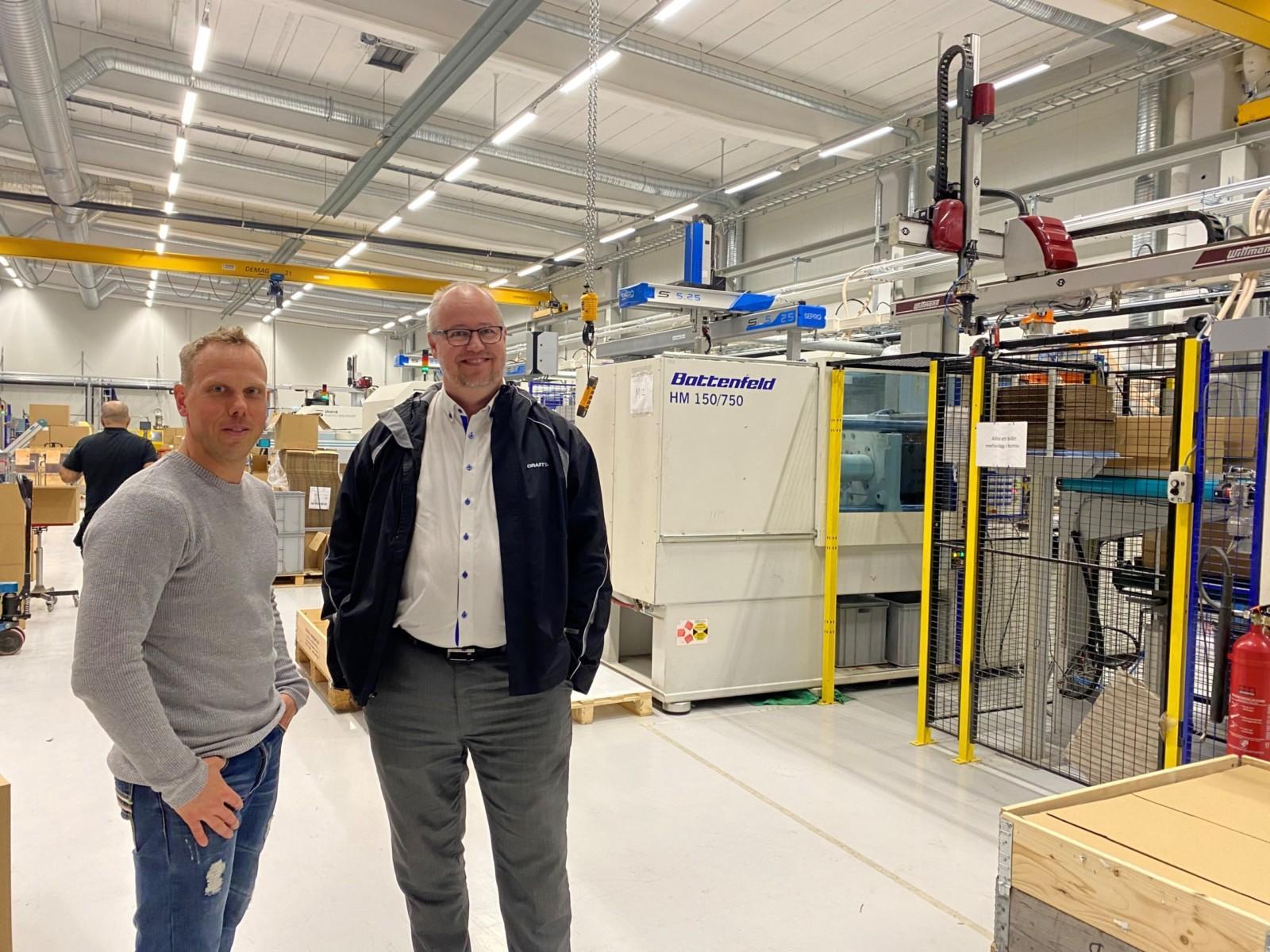

Andreas Rosell, Department Manager Logistics and Production at Fresh (left) and Christian Funk, JLT’s Director Product Marketing and Business Development (right) stand in the new Fresh warehouse in Växjö, Sweden.

JLT Mobile Computers joins the new facilities

In the new facilities of around 8,000 square meters there are about 65 Fresh employees and an additional 50 hired fitters and packers from Samhall, a Swedish state-owned company that employs people with disabilities with the purpose to build a more inclusive society. The facilities include offices, plastic production, spiro manufacturing, mounting and warehouse facilities.

In the warehouse all forklifts are equipped with devices from JLT.

“We used rugged computers from JLT on the forklifts in our previous facility. Since they had been working really well, of course we wanted to bring them with us when we moved. As the company has continued to grow, we recently needed more forklifts and got new computers of the same JLT model that we already had to go with them.”

When the business expands again, Fresh intend to get picking trucks that will be equipped with forklift computers and scanners to simplify the daily work.

The cheapest option isn’t always best

Investing in forklift computers and IT equipment obviously entails a cost, but the returns in terms of increased efficiency and smoother work for employees make it worth it.

“Of course, there’s a cost, but we see it as an investment. We did our calculations and it became clear that it’s not the cheapest forklift or computer that wins in the long run. I understand it’s easy to go with the cheaper solution if you have a short-term perspective, but we take the total cost of ownership into account and are keen to choose the solution that suits our operation best. Monetarily the investment has already paid off and we’ve also gained a close relation to JLT. Knowing that we will always get the help we need is very valuable and reassuring”, says Andreas.

Anders Ekholm works as a forklift driver at Fresh and tells us about his everyday work.

“To me, the forklift, my scanner and the JLT computer are my most important working tools. I’m fully relying on these to be able to do my job. I get immediate access to information through the computer, which is crucial for the entire warehouse logistics flow to function.”

A bright future ahead for Fresh

Andreas Rosell is positive about the future and is looking forward to driving the continued development of the company.

“My work is very rewarding and there is so much potential. I’m looking forward to continuing the development of our business and to increase the integration with the other companies within the group. I want us to share a central warehouse of the future in these facilities” says Andreas.

Want to learn more?

We’re here to help and advise you on every aspect of rugged devices and industry data communications.

Please fill in the form and we will get back to you as soon as possible.